Grinding media plays a fundamental role in a variety of industrial processes, especially those involving size reduction, mixing, or dispersion of particles. Whether in mining, cement manufacturing, or chemical production, grinding media is at the heart of the comminution process. But what exactly is grinding media? How does it function? And why is it so crucial in today’s material processing industries?

In this comprehensive article, we’ll explore the working principle, types, characteristics, and industrial applications of grinding media, while also addressing common questions in a FAQ section and providing helpful tabulated data for better clarity.

Understanding the Basics: What Is Grinding Media?

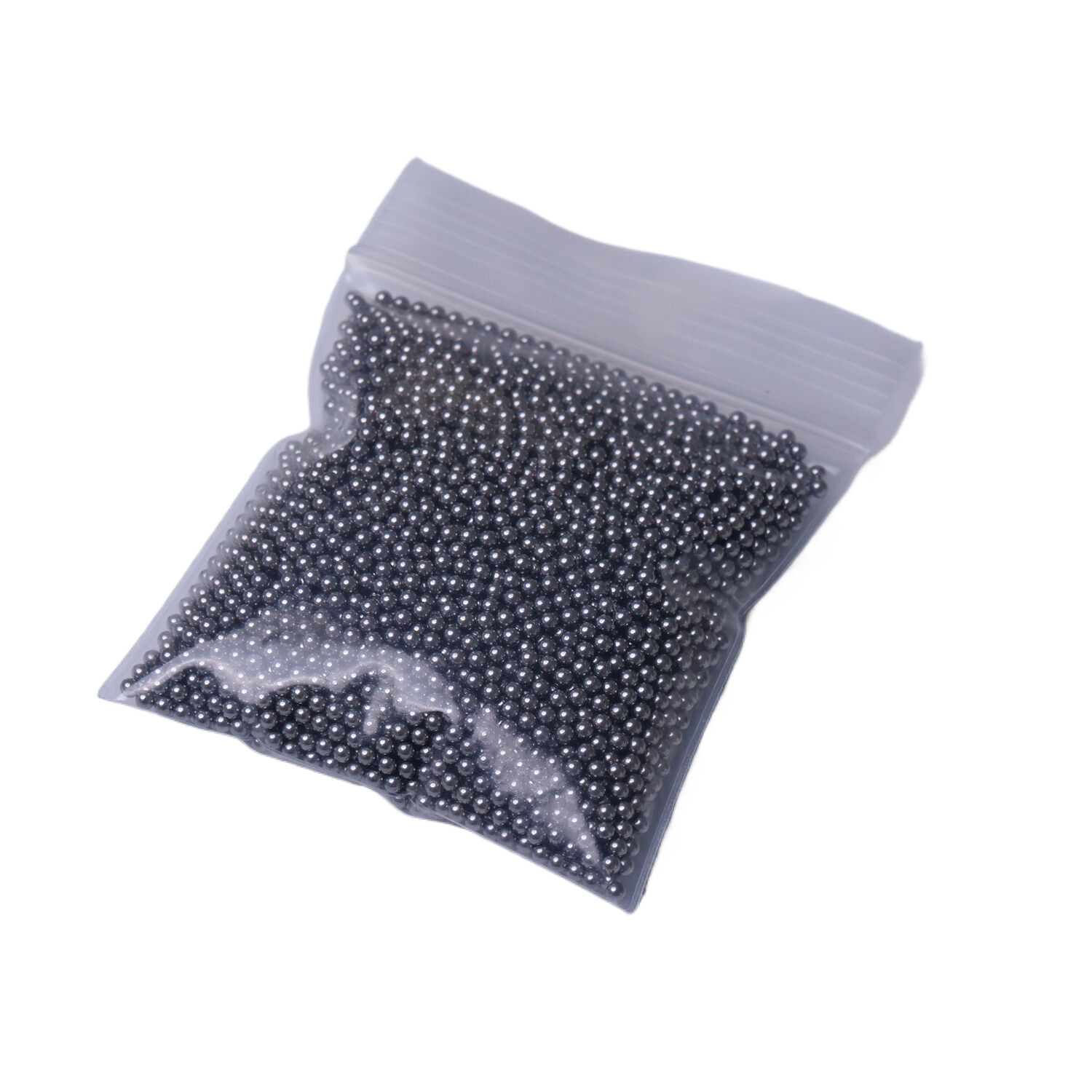

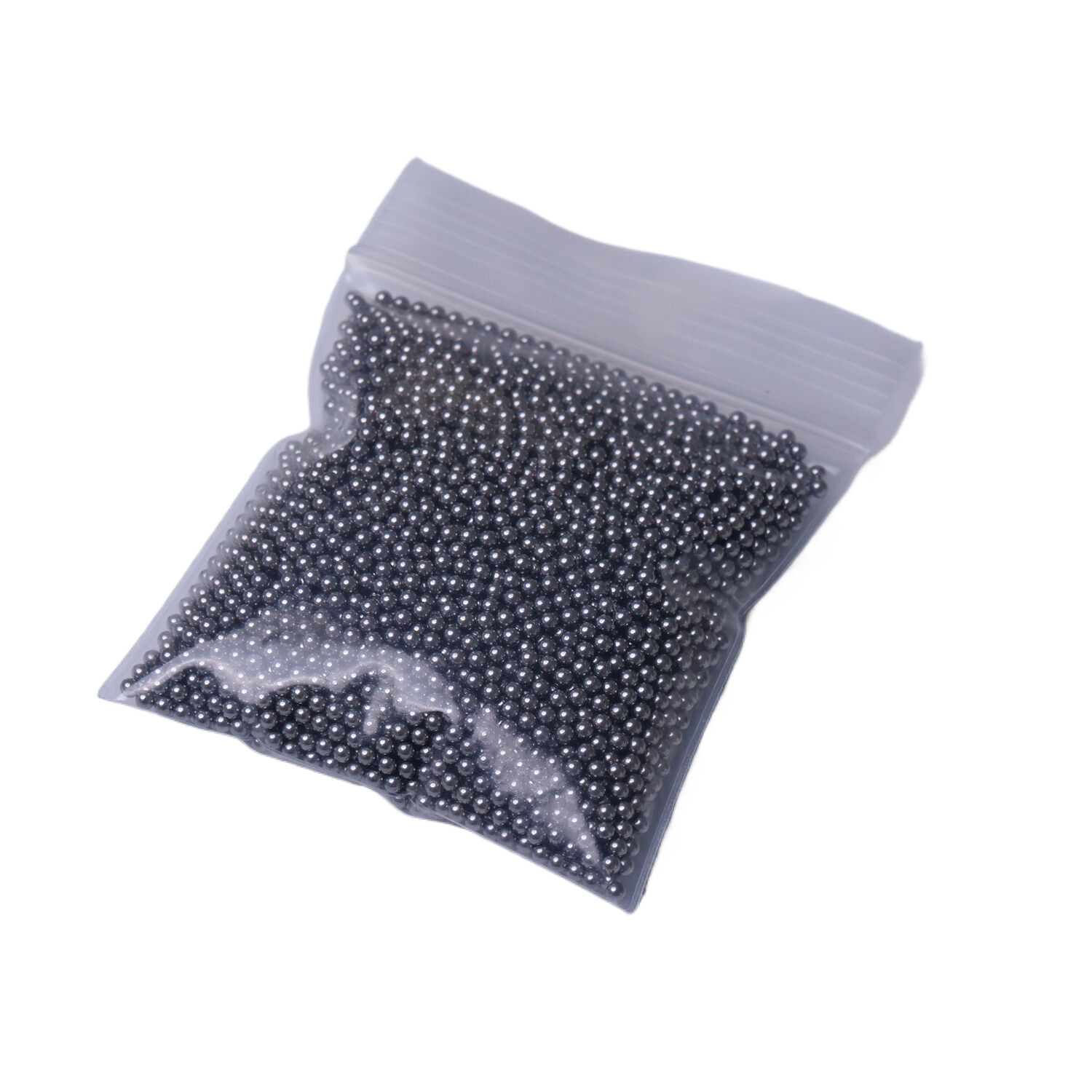

Grinding media refers to the solid materials—typically balls, beads, rods, or cylpebs—used in grinding mills to crush or grind materials into smaller particles. These media materials are introduced into mills, such as ball mills, rod mills, or SAG mills, where they interact with the material being processed through impact, attrition, or abrasion.

Grinding media serves as the medium through which kinetic energy is transferred from the rotating or vibrating mill to the raw material, breaking it down into the desired particle size. The efficiency and final output of grinding operations heavily depend on the characteristics of the grinding media used.

Common materials used for grinding media include:

Steel (carbon steel, stainless steel)

Ceramic (alumina, zirconia)

Glass

Forged cast iron

The selection of grinding media is not arbitrary. It depends on several factors such as hardness of the feed material, the milling process type (wet or dry), contamination tolerance, and the final particle size required.

How Does Grinding Media Work in a Milling Process?

Grinding media works by applying mechanical forces to materials placed inside a rotating or vibrating mill. These forces cause the media to impact and grind the feed particles. The motion of the grinding media creates a dynamic environment where large particles are broken down into smaller, finer ones.

There are generally three types of mechanical actions that grinding media facilitate:

Impact – Media falls or is lifted and dropped onto the material, breaking it via direct collision.

Attrition – Particles are ground through rubbing and friction between the media and material.

Shear – The motion causes particles to be crushed between moving surfaces.

Each type of mill operates differently:

Ball mills rely heavily on impact and attrition.

Rod mills emphasize cascading and rolling motion.

Stirred media mills offer high energy density and are preferred for ultrafine grinding.

The design of the mill, speed of rotation, load level, and the type and size of grinding media all influence the efficiency and effectiveness of the grinding process.

Types of Grinding Media: Choosing the Right One

Choosing the appropriate grinding media depends on the application. Different types are optimized for different processes, materials, and desired outcomes. Below is a comparison table highlighting key characteristics:

| Type |

Material |

Typical Use |

Advantages |

| Steel Balls |

Carbon/Stainless Steel |

Mining, Cement |

High density, durability |

| Ceramic Beads |

Alumina/Zirconia |

Paint, Pharmaceuticals |

Low contamination, inert |

| Glass Beads |

Soda-lime glass |

Food, Cosmetics |

Cost-effective, non-toxic |

| Rods |

Steel |

Ore grinding (Rod Mills) |

Linear motion, low fines |

| Cylpebs |

Cast Iron |

Intermediate particle sizes |

Higher surface area contact |

Each grinding media has its own hardness, wear resistance, and cost, and these factors should be considered carefully based on the process needs. Ceramic and glass beads are favored for their low reactivity, while steel balls are best for high-impact applications.

Industrial Applications of Grinding Media

Grinding media is indispensable in industries where precision and performance are key. Its versatility is evident across sectors such as:

Mining and Mineral Processing: Used extensively in grinding ores to extract valuable metals.

Cement Industry: Helps in grinding clinker into fine powder for cement production.

Paints and Coatings: Enables uniform dispersion of pigments and stabilizers.

Pharmaceuticals: Used in micronization of active ingredients for better absorption.

Food Processing: Assists in grinding spices, sugar, and other food ingredients.

In each application, the effectiveness of grinding media directly impacts productivity, energy consumption, and product quality. Industries invest heavily in choosing media that offer the perfect balance between efficiency and operational cost.

FAQs: Frequently Asked Questions About Grinding Media

What size grinding media should I use?

The size depends on the mill type and the material you’re processing. For coarse grinding, larger media (20–50 mm) is used, while finer media (0.1–5 mm) is preferred for ultrafine grinding or dispersion.

How long does grinding media last?

The lifespan varies significantly. Steel media may last several months in a heavy-duty operation, whereas glass beads may wear out faster depending on the application. Monitoring wear rate is essential for timely replenishment.

Can grinding media contaminate the product?

Yes. That’s why inert materials like zirconia or alumina are used in applications where contamination must be avoided, such as food and pharmaceuticals.

How do I clean grinding media?

Cleaning involves washing with water or suitable solvents, followed by drying. In high-purity operations, ultrasonic cleaning may be necessary.

Key Factors to Consider When Selecting Grinding Media

Several key considerations influence the selection of grinding media:

Hardness and Density: Heavier media offers more impact force, improving grinding efficiency.

Chemical Compatibility: Choose inert media for processes sensitive to contamination.

Wear Resistance: Long-lasting media reduces replacement frequency and operational cost.

Shape and Surface Area: Spherical media promotes smoother motion, while irregular shapes increase shear.

Balancing all these factors is essential to achieving desired performance while minimizing downtime and cost.

Conclusion: Why Grinding Media Matters

Grinding media may appear simple at first glance, but its function in industrial processing is pivotal. It transforms raw material into usable products, drives innovation in material science, and significantly affects productivity and energy consumption.