Grinding mills are pivotal to many industrial processes, serving as the backbone of material reduction in sectors like mining, cement, chemical processing, and ceramics. Among the crucial components that define their efficiency and performance is grinding media. But what exactly is a grinding mill used for, and how does grinding media play a vital role in its operation? This article explores these questions in detail.

Understanding the Role of a Grinding Mill

A grinding mill is an industrial machine designed to reduce large solid materials into finer particles. This reduction process is essential for downstream processing or material transformation in various industries. Mills come in several types—ball mills, rod mills, SAG mills, and vertical roller mills—all designed to perform the same core function but with variations in mechanics and efficiency.

The primary uses of a grinding mill include:

Ore processing in the mining industry, where minerals are reduced to liberate valuable elements like gold or copper.

Cement manufacturing, where clinker and additives are ground into fine powder to produce cement.

Chemical blending, which requires consistent particle size for product homogeneity.

Food and pharmaceutical grinding, ensuring ingredients meet regulatory particle size requirements.

These functions are made possible and efficient through the application of the right grinding media.

What Is Grinding Media?

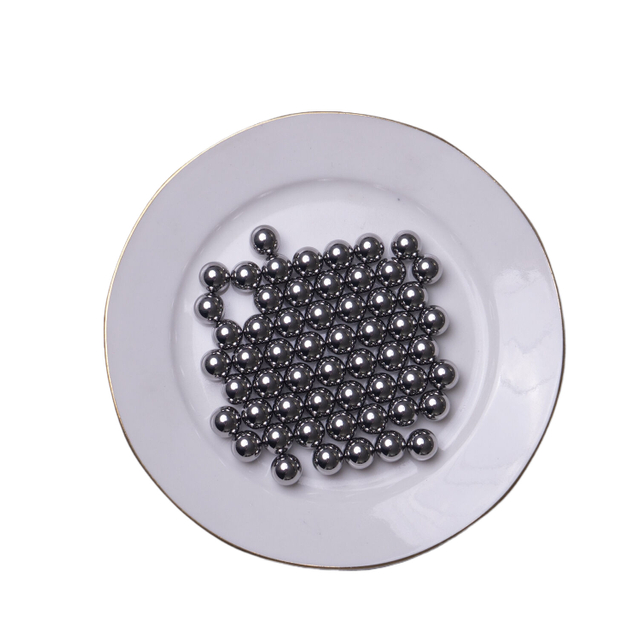

Grinding media refers to the materials—typically steel balls, ceramic beads, or high-density alumina—that are used inside grinding mills to break down materials through impact and attrition. Depending on the application, the type, shape, and size of the grinding media can drastically affect the efficiency, wear rate, and output quality of the grinding process.

Types of Grinding Media

| Grinding Media Type | Common Material | Key Application | Hardness Level |

| Steel Balls | Carbon/Alloy Steel | Mining, Cement | High |

| Ceramic Beads | Zirconia, Alumina | Pharmaceuticals, Paints | Medium-High |

| Forged Balls | Alloy Steel | Gold/Copper Ores | Very High |

| Glass Beads | Soda-lime Glass | Cosmetic, Fine Chem | Medium |

The selection of grinding media is highly dependent on the mill type, material hardness, and desired final particle size. Using inappropriate media can lead to contamination, increased wear, and energy inefficiency.

How Does Grinding Media Work in a Grinding Mill?

Grinding media acts as the catalyst in the milling process. Inside the rotating chamber of the mill, media is lifted and dropped by rotational forces. This motion generates impact and frictional forces against the feed material, fracturing it into finer particles.

The grinding process involves two primary mechanisms:

Impact Crushing: When larger media falls from the top of the mill, it crushes particles below.

Attrition Grinding: As particles are trapped between media pieces, they are ground down through friction.

The media-to-material ratio, mill speed, and media density directly influence the effectiveness of grinding. Denser media generates greater impact, making it suitable for tougher materials, whereas lighter media is preferred for softer or heat-sensitive applications.

Factors That Affect Grinding Mill Efficiency

While grinding media is a core component, several other factors contribute to the operational efficiency of a grinding mill:

1. Mill Type and Design

Different mills are optimized for different particle size targets. For instance, ball mills are better suited for coarse grinding, while attritor mills are more efficient for fine or nano grinding.

2. Media Size Distribution

Using a uniform size of grinding media may not yield the best results. A graded mix of media sizes allows for better coverage of various particle sizes in the feed, enhancing grinding efficiency.

3. Rotation Speed

Each mill has a critical speed—the speed at which grinding media no longer falls but centrifuges along the wall. Operating slightly below this speed maximizes impact forces.

4. Material Properties

Feed materials that are abrasive or moisture-sensitive can influence both media wear rate and mill performance.

Advantages of Using the Right Grinding Media

The benefits of choosing the correct grinding media are significant:

Improved throughput: Higher grinding efficiency reduces processing time.

Consistent product quality: Proper media delivers uniform particle size distribution.

Extended equipment life: Correct media minimizes internal mill wear.

Reduced operational cost: Efficient media reduces energy and media consumption per ton.

The wrong choice, however, can lead to product contamination, uneven milling, and increased maintenance costs.

Frequently Asked Questions About Grinding Mills and Grinding Media

Q1: Can grinding media be reused?

Yes, in many cases, grinding media can be reused multiple times. However, wear and contamination levels must be monitored to determine when replacement is necessary.

Q2: What size of grinding media should I use?

The media size depends on the desired final particle size and the mill type. Generally, smaller media produce finer particles but may require longer processing times.

Q3: How do I know when to replace grinding media?

Signs include reduced grinding efficiency, excessive contamination, increased energy consumption, or visible flattening or fragmentation of the media.

Q4: Can grinding media affect product purity?

Absolutely. In industries like pharmaceuticals or electronics, non-metallic or ceramic media are used to prevent metallic contamination.

Choosing the Right Grinding Media for Your Application

The selection of grinding media should be based on a combination of process requirements, material characteristics, and economic considerations. Here's a quick guide:

| Application | Recommended Media Type | Consideration |

| Mining | Forged Steel Balls | Wear resistance, hardness |

| Paint & Ink | Ceramic Beads | Smooth finish, non-reactive |

| Pharmaceuticals | Zirconia Beads | Purity, particle uniformity |

| Cement | High Chrome Steel Balls | Cost efficiency, durability |

Choosing high-quality grinding media not only improves performance but also supports sustainable operation by reducing waste and energy use.

Conclusion

Grinding mills are indispensable in modern industry, acting as the transformative force that converts raw materials into workable forms. Whether it’s breaking down ore in a gold mine or creating ultra-fine powders for pharmaceuticals, the effectiveness of a grinding mill depends heavily on the grinding media used.

By understanding how grinding media interacts with the material and the mill itself, operators can fine-tune their processes for optimal performance, cost savings, and product quality. The right grinding media is not just an accessory—it’s an essential partner in the milling journey.