Introduction

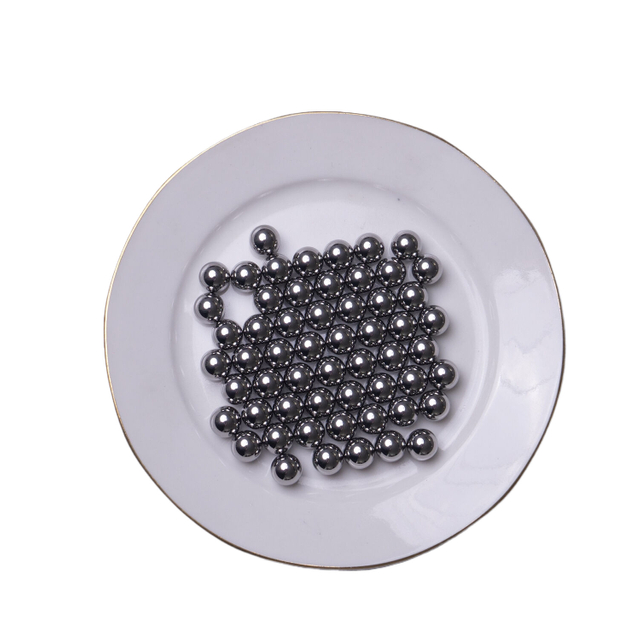

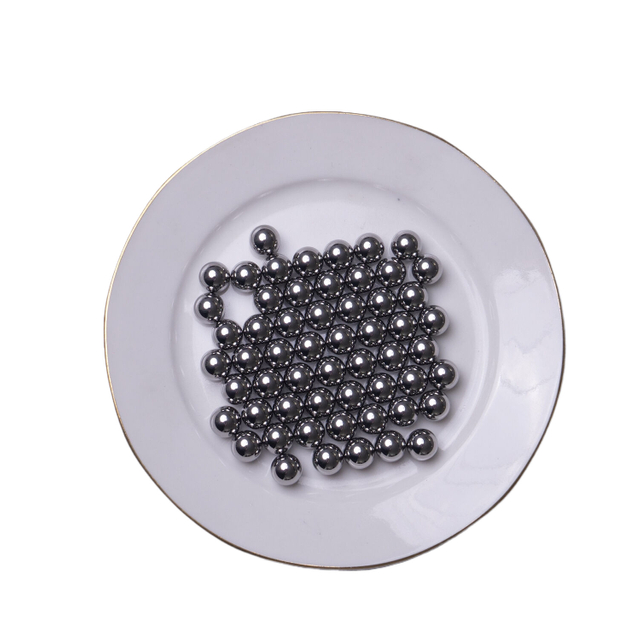

Stainless steel balls may seem like small, insignificant components in the grand design of machinery, but in reality, they play a pivotal role in various industries. These spherical components are crafted from high-grade stainless steel, providing outstanding corrosion resistance, hardness, and strength. Whether you are dealing with automotive systems, medical equipment, or even cosmetic products, chances are you’ll find stainless steel balls quietly performing critical tasks behind the scenes.

This article explores the widespread uses of stainless steel balls, outlining their roles across multiple sectors and emphasizing why they’re indispensable in modern technology and manufacturing.

Industrial Applications – The Backbone of Mechanical Systems

Precision Bearings and Mechanical Motion

One of the most prevalent applications of stainless steel balls is in bearing systems. Ball bearings reduce friction and enhance motion in a wide range of machines, from bicycles and automobiles to industrial fans and robotics. Stainless steel is preferred due to its excellent wear resistance and ability to operate under high-stress conditions without deforming.

In these bearings, stainless steel balls act as rolling elements that allow shafts and axles to rotate smoothly and efficiently. They must endure immense loads and repetitive movement, which is why precision manufacturing is crucial. The uniformity and smoothness of stainless steel balls enable mechanical systems to function reliably for extended periods without maintenance.

Valves and Fluid Control Systems

In fluid handling systems, stainless steel balls are used in valves—particularly ball valves. These are critical in controlling the flow of liquids and gases in pipelines. The ball component rotates to either block or allow flow, making it essential for applications that require precision flow control.

Industries such as oil and gas, food processing, pharmaceuticals, and water treatment facilities depend heavily on these valves. Stainless steel balls in such valves provide leak-proof, hygienic, and corrosion-resistant performance, making them ideal for handling aggressive chemicals and high-pressure liquids.

Medical and Pharmaceutical Uses – Where Precision Meets Hygiene

Medical Equipment and Surgical Tools

Stainless steel balls are also found in medical devices and surgical instruments. Their biocompatibility and resistance to corrosion from bodily fluids and cleaning agents make them ideal for such applications. These balls are used in medical pumps, check valves, and atomizers, all of which require absolute precision and cleanliness.

Moreover, miniature stainless steel balls are often utilized in diagnostic devices and imaging equipment to enable precise mechanical movements without introducing contaminants or reacting with sensitive chemical substances.

Drug Manufacturing Processes

In the pharmaceutical industry, stainless steel balls are frequently used in ball mills for mixing and grinding active pharmaceutical ingredients (APIs). These balls enable uniform particle size distribution, which is crucial for consistent drug performance and safety.

The non-reactive nature of stainless steel ensures that no unwanted residues or chemical reactions compromise the integrity of the medication, maintaining high purity and quality standards.

Automotive and Aerospace – Enhancing Durability and Performance

Transmission Systems and Steering Mechanisms

In automobiles, stainless steel balls are integral to transmission systems, steering mechanisms, and other moving components. Their strength and resilience against high-speed rotation and variable temperatures ensure reliable performance over long periods.

For instance, in gearboxes and drive shafts, stainless steel balls help reduce vibration and improve fuel efficiency. Their precision and load-bearing capacity are vital in environments where reliability directly impacts safety and performance.

Aerospace Navigation and Actuation Systems

The aerospace sector requires components that can withstand extreme conditions—ranging from vacuum and zero gravity to fluctuating temperatures. Stainless steel balls find use in navigational instruments, actuation systems, and satellite components, providing high tolerance and minimal weight without sacrificing strength.

Their smooth operation and resistance to oxidation make them essential for ensuring the long-term reliability of space and aircraft systems.

Consumer Goods and Everyday Items – The Unsung Heroes

Cosmetics, Sprayers, and Ballpoint Pens

While industrial applications dominate, stainless steel balls are also used in everyday products. A notable example is cosmetic packaging, where stainless steel balls serve as mixing components in nail polish bottles or roll-on applicators. They help maintain consistency and ensure even application.

In spray pumps and aerosol cans, they act as one-way valves, enhancing spray efficiency and preventing leakage. Even ballpoint pens utilize miniature stainless steel balls at the tip, enabling smooth ink flow and long-lasting functionality.

Home Appliances and Tools

From blenders and coffee grinders to power tools and gardening equipment, stainless steel balls play a vital role in ensuring the durability and functionality of rotating parts. Their presence allows for smoother operation and longer service life of appliances that most people use without a second thought.

Food and Beverage Industry – Hygienic and Safe Solutions

Processing Machinery and Mixing Systems

In food production, hygiene and corrosion resistance are paramount. Stainless steel balls meet these criteria, making them a preferred choice for food-grade machinery, such as meat grinders, food processors, and mixers. Their non-reactive surface ensures that they do not alter the taste, smell, or safety of food products.

Additionally, their ability to withstand frequent washing and exposure to acids and alkalis used in cleaning agents makes them indispensable in maintaining food safety standards.

Packaging and Dispensing Equipment

Stainless steel balls are also found in packaging equipment that dispenses sauces, beverages, and powdered ingredients. Here, they serve in pump mechanisms and check valves, helping to control the flow of materials and ensure accurate portioning without contamination.

Comparative Table – Key Features of Stainless Steel Balls by Application

| Application Area | Required Properties | Common Ball Grades | Size Range |

| Bearings | High hardness, wear resistance | 420C, 440C | 1mm – 50mm |

| Valves | Corrosion resistance, precision | 304, 316 | 3mm – 100mm |

| Medical Devices | Biocompatibility, corrosion resistance | 316L | 0.5mm – 20mm |

| Automotive/Aerospace | Strength, temperature resistance | 440C, 630 | 1mm – 25mm |

| Consumer Products | Smooth surface, durability | 201, 304 | 0.5mm – 10mm |

| Food Industry | Non-toxic, hygienic, acid-resistant | 316, 316L | 2mm – 30mm |

FAQ – Common Questions About Stainless Steel Balls

Are all stainless steel balls magnetic?

Not all stainless steel balls are magnetic. For example, balls made from 304 or 316 stainless steel are generally non-magnetic, while those made from 420 or 440C grades tend to be magnetic due to their martensitic structure.

Can stainless steel balls rust?

Under most conditions, stainless steel balls are highly resistant to rust. However, in extremely corrosive environments or if low-grade stainless steel is used, some surface oxidation may occur over time. Using higher grades like 316L can significantly mitigate this risk.

How are stainless steel balls manufactured?

They are typically made through a cold heading process, followed by flashing, heat treatment, grinding, lapping, and polishing. Each stage ensures the ball meets strict tolerance, hardness, and surface finish requirements.

Conclusion

Stainless steel balls may be small, but their contribution to modern industry and daily life is immense. Their versatility, strength, and resistance to wear and corrosion make them indispensable in countless applications—from high-precision aerospace instruments to your everyday ballpoint pen. Understanding their roles and properties allows industries and consumers alike to appreciate the engineering marvels behind seemingly simple components.