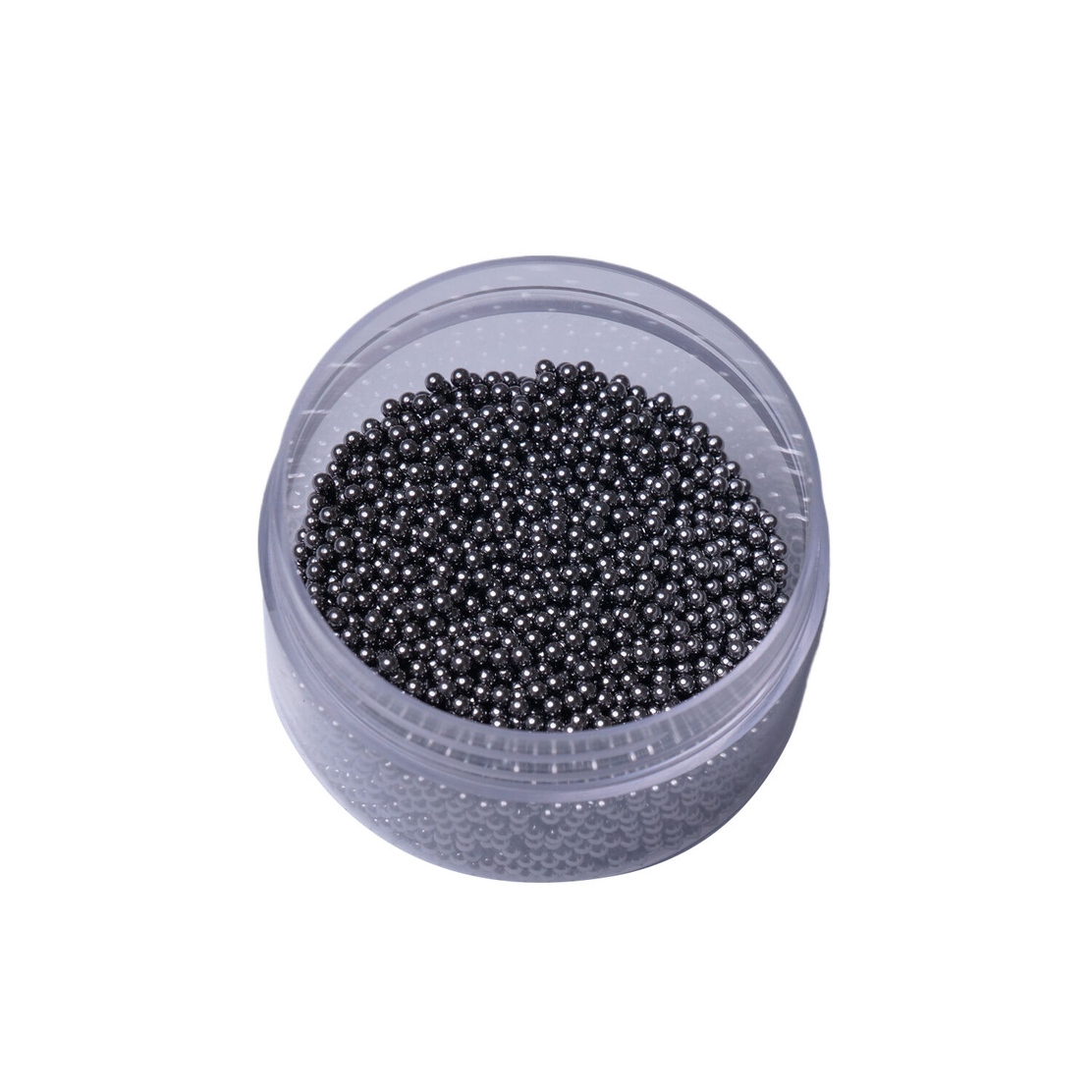

Introduction to Stainless Steel Ball

Stainless steel balls are spherical components manufactured from stainless steel—a metal alloy known for its strength, corrosion resistance, and durability. These small yet vital parts are used in a variety of industries, ranging from automotive and aerospace to medical equipment and food processing. What makes stainless steel balls so indispensable is not just their robust physical structure, but also their ability to withstand extreme environments, whether exposed to moisture, chemicals, or high-pressure systems.

The manufacturing process of stainless steel balls is rigorous and standardized. Typically, the production involves forging, heat treatment, grinding, and polishing. Each stage is carefully monitored to ensure consistency in size, surface finish, hardness, and sphericity. This precision allows stainless steel balls to perform reliably in mechanical systems such as bearings, valves, pumps, and spray devices.

Choosing stainless steel over other materials like plastic, ceramic, or carbon steel is often a decision driven by performance requirements. For example, in marine or corrosive environments, stainless steel balls outperform alternatives due to their rust-resistant properties. Therefore, understanding their characteristics and selection criteria is essential for engineers, buyers, and manufacturers alike.

Properties of Stainless Steel Ball

Material Composition and Grades

Stainless steel balls come in various grades, each offering unique characteristics. The most common types include AISI 304, 316, and 440C. Here's a comparison table for reference:

| Grade | Corrosion Resistance | Hardness (HRC) | Magnetism | Typical Applications |

| 304 | High | 25-39 | Non-magnetic | Food industry, medical tools |

| 316 | Very High | 25-39 | Non-magnetic | Marine equipment, valves |

| 440C | Moderate | 58-65 | Magnetic | Bearings, aerospace parts |

Each of these grades has a specific purpose. For instance, 316 stainless steel balls are ideal for marine environments due to their high molybdenum content, which enhances corrosion resistance. On the other hand, 440C stainless steel balls are hardened for use in applications requiring high wear resistance.

Mechanical and Thermal Properties

Stainless steel balls are designed to endure significant mechanical stress. They feature excellent tensile strength, typically exceeding 500 MPa, and their thermal expansion coefficients remain stable under changing temperatures. Furthermore, stainless steel balls have a high melting point, usually above 1400°C, making them suitable for high-temperature applications.

Another critical property is surface finish. High-precision stainless steel balls often achieve finishes as fine as 10 microinches or better, reducing friction and wear in dynamic systems.

Applications of Stainless Steel Ball

The versatility of stainless steel balls means they are used across a broad range of sectors:

Automotive and Aerospace

In the automotive industry, stainless steel balls are used in critical components such as ABS systems, fuel injection systems, and bearings. Their reliability under high-stress conditions makes them indispensable in these safety-related applications. In aerospace, stainless steel balls find use in control systems, valves, and guidance mechanisms, where any failure could lead to catastrophic outcomes.

Medical and Food Processing

Due to their hygienic and non-reactive nature, stainless steel balls are widely used in medical devices and food-grade equipment. They are essential in tools like syringes, surgical instruments, and mixers, where cleanliness and non-contamination are crucial. The non-porous surface of stainless steel ensures that no bacteria or food particles are retained, making them easy to sterilize and reuse.

Industrial Machinery and Consumer Products

In industrial setups, stainless steel balls are used in conveyor systems, spray pumps, and valves. In consumer products, you’ll find them in pens, locks, and cosmetic applicators. The uniformity and strength of these balls ensure product longevity and consistent performance.

How to Choose the Right Stainless Steel Ball

Selecting the right stainless steel ball requires understanding several key factors:

Environment – Is the application exposed to moisture, chemicals, or high temperatures?

Load and Wear – Will the ball experience high loads or abrasive forces?

Size and Precision – What are the dimensional tolerances required?

Here’s a quick decision matrix to help:

| Requirement | Recommended Grade |

| Corrosive Environments | 316 |

| High Wear Resistance | 440C |

| Non-Magnetic Needs | 304 or 316 |

Evaluating these aspects ensures longevity and cost-efficiency. A mismatch between the grade and application can lead to premature failure, safety hazards, or increased maintenance costs.

Frequently Asked Questions (FAQ)

Are stainless steel balls truly rust-proof?

Stainless steel is highly resistant to rust, but not completely rust-proof. Grades like 316 offer excellent corrosion resistance, especially in saltwater or chemical environments. However, under extreme conditions or improper maintenance, even stainless steel may develop surface rust or pitting.

Can stainless steel balls be recycled?

Yes, stainless steel balls are fully recyclable. Their metallic composition allows them to be melted down and reused without significant loss of properties. This makes them an eco-friendly choice for sustainable manufacturing practices.

What is the lifespan of a stainless steel ball?

The lifespan depends on the operating environment, load, and maintenance. In ideal conditions, a high-grade stainless steel ball can last several years without any degradation in performance. Regular lubrication and avoiding corrosive exposure can significantly extend their usability.

Maintenance and Storage Best Practices

Proper maintenance is critical to maximizing the service life of stainless steel balls. Despite their robust design, they still require care, especially when used in high-precision systems. Here are some best practices:

Cleaning: Always clean the balls with a non-corrosive solvent to remove dust, oil, or debris. Avoid using harsh chemicals that may degrade the steel’s passive layer.

Lubrication: Use suitable lubricants if the balls are used in dynamic systems. This reduces wear and enhances smooth operation.

Storage: Keep stainless steel balls in a dry, controlled environment. Avoid exposing them to moisture, acids, or salts during storage.

Implementing these practices ensures that your investment in stainless steel balls delivers optimal performance over time.