Introduction

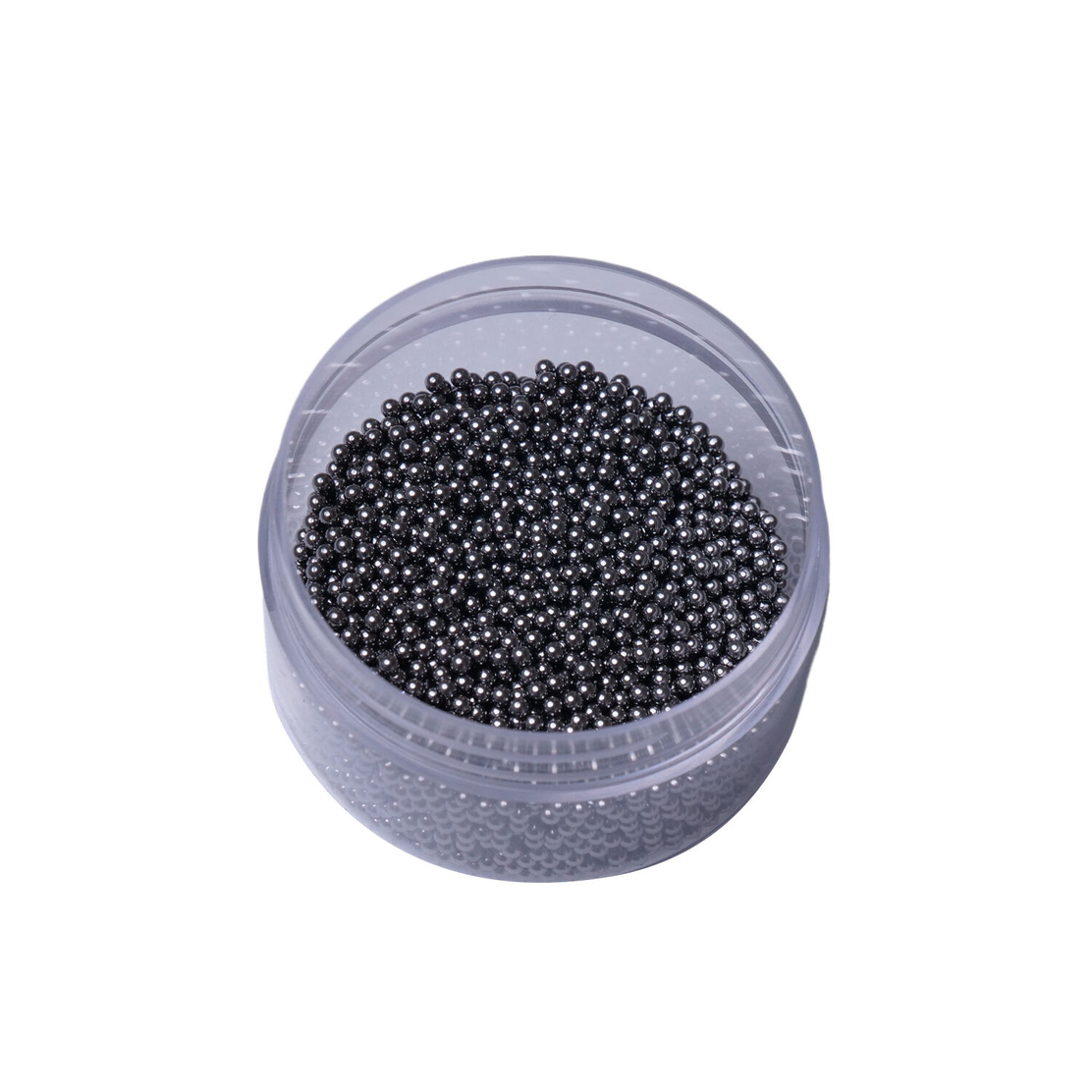

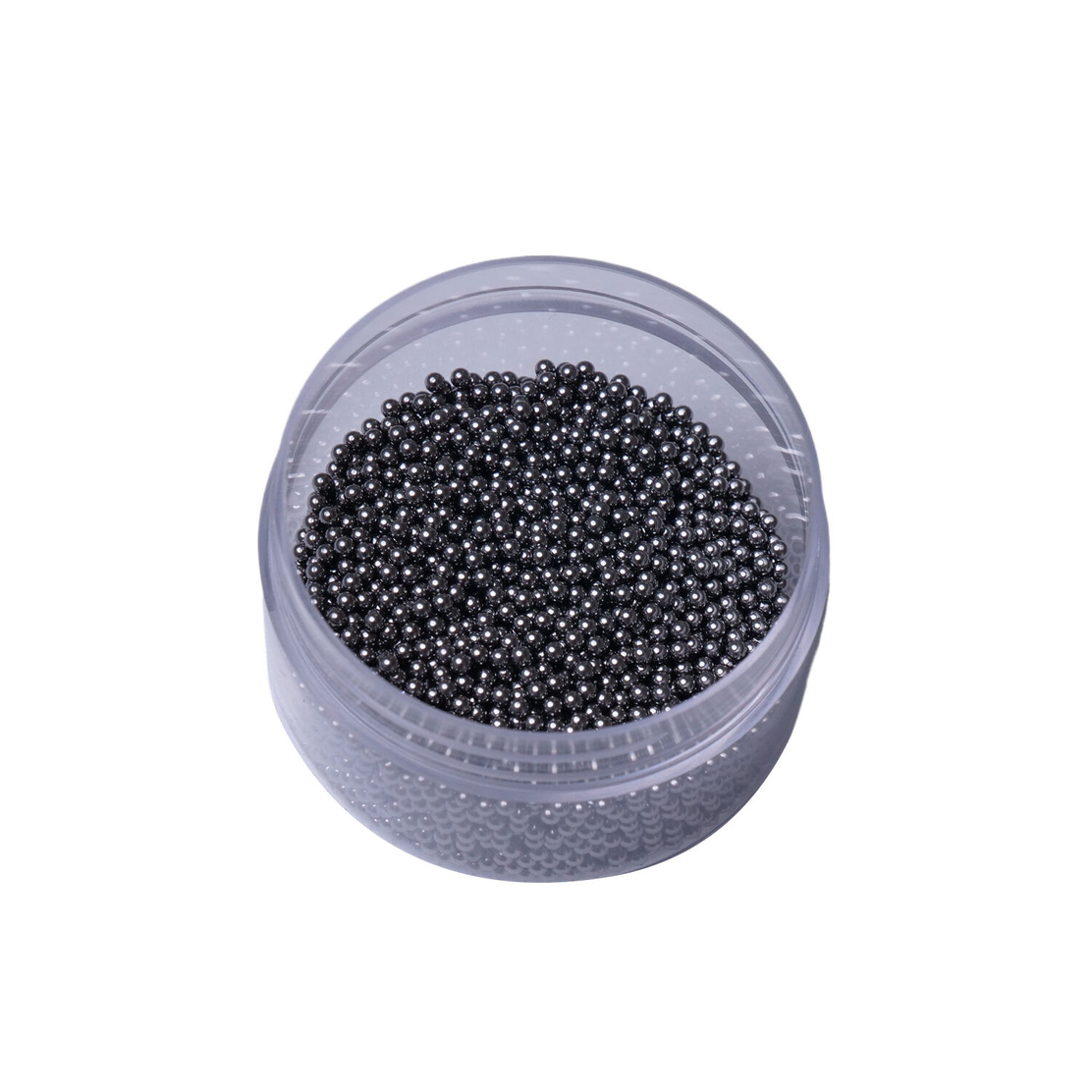

Stainless steel ball bearings are essential components in countless industries — from automotive to aerospace, from household appliances to precision instruments. The allure of stainless steel lies in its robust mechanical properties, corrosion resistance, and long service life. But despite the name "stainless," a common question arises: do stainless steel ball bearings rust? This seemingly simple question touches on complex metallurgical principles, environmental factors, and maintenance practices. In this article, we’ll explore the truth behind stainless steel corrosion, clear up misconceptions, and help you understand when, why, and how stainless steel ball bearings might actually rust under certain conditions.

What Makes Stainless Steel 'Stainless'?

To understand whether stainless steel ball bearings rust, we need to examine the metal’s composition. Stainless steel is an iron-based alloy containing at least 10.5% chromium, which forms a passive oxide layer on the surface. This thin but resilient layer protects the steel from environmental attack and oxidation.

Ball bearings made from stainless steel often use grades like AISI 440C, AISI 304, and AISI 316, each with varying levels of chromium, carbon, nickel, and molybdenum. The type of stainless steel selected plays a crucial role in the bearing's performance in different environments. For example:

| Stainless Steel Grade |

Chromium (%) |

Key Property |

Typical Use Case |

| AISI 440C |

16-18 |

High hardness, wear resistance |

Precision bearings |

| AISI 304 |

18-20 |

Excellent corrosion resistance |

Food processing |

| AISI 316 |

16-18 |

Superior resistance to salt water |

Marine environments |

Despite these advantages, stainless steel is not completely immune to corrosion. When the protective chromium oxide layer is compromised — through mechanical damage, chloride exposure, or high humidity — rusting can occur.

When Do Stainless Steel Ball Bearings Rust?

Stainless steel ball bearings are engineered for durability, but certain scenarios make them vulnerable. The most common cause of rust is prolonged exposure to harsh environments such as:

High chloride areas (e.g., coastal regions or salt spray)

Industrial environments with acidic or basic vapors

Trapped moisture or water droplets inside housing systems

Lack of lubrication or protective coating

Once the protective oxide layer is penetrated or overwhelmed, the iron content in the stainless steel begins to oxidize, forming rust. This process can be localized (pitting corrosion) or widespread, depending on the severity and nature of the exposure.

It’s important to note that visible rust is not always widespread corrosion. In many cases, a small surface rust spot may not compromise the structural integrity of the bearing if detected and treated early. However, if ignored, corrosion can spread and significantly reduce performance.

Can Stainless Steel Rust Without Water?

This question surprises many — can something rust without direct water contact? Technically, no. Rust, by definition, requires both oxygen and water (or high humidity) to form iron oxide. But in practice, even ambient humidity levels above 60%, particularly when combined with contaminants or salt particles, can initiate the corrosion process.

Furthermore, stainless steel ball bearings installed in sealed but non-ventilated systems can suffer from condensation, creating micro-water environments perfect for rust development. This is especially relevant in:

Preventive design, proper sealing, and ventilation are crucial to prevent these micro-environments from forming.

How to Prevent Stainless Steel Ball Bearings from Rusting

While it’s impossible to make any material 100% rust-proof, the right preventative strategies can make rusting extremely rare for stainless steel ball bearings. Here are essential practices:

Material Selection

Use the appropriate stainless steel grade for the environment. For high-chloride settings, AISI 316 is often more reliable than 440C.

Proper Lubrication

Lubricants act as a barrier between the bearing and moisture. Use corrosion-inhibiting greases or oils designed for stainless steel.

Controlled Environment

Maintain low humidity where possible. Avoid storing bearings in unventilated, damp spaces.

Regular Inspection and Cleaning

Periodically check for discoloration, moisture accumulation, or rough rotation. Clean bearings with appropriate solvents and reapply protective lubricants.

Avoid Contact with Carbon Steel Tools or Surfaces

Cross-contamination can introduce iron particles to the stainless steel surface, leading to localized rust (a phenomenon called “tea staining”).

FAQs About Stainless Steel Ball Bearings and Rust

Q1: Will 304 stainless steel bearings rust in saltwater?

Yes, over time. 304 stainless steel is not marine-grade. 316 stainless steel is more suitable due to added molybdenum which resists salt corrosion.

Q2: Can I use WD-40 on stainless steel bearings?

Yes, but only as a short-term moisture displacement. For long-term use, apply bearing-specific greases or oils with corrosion inhibitors.

Q3: Is discoloration on stainless steel always rust?

No. Discoloration may be heat tinting or surface contamination. Rust is typically reddish-brown and flaky.

Q4: What is the lifespan of stainless steel ball bearings?

In optimal conditions, they can last tens of thousands of hours. Poor maintenance or harsh environments reduce lifespan dramatically.

Q5: Can ultrasonic cleaning remove rust from stainless steel bearings?

Yes, in combination with rust-removal solutions. However, it should be followed by drying and re-lubrication to prevent re-rusting.

Conclusion

So, do stainless steel ball bearings rust? Yes, but only under specific conditions that compromise the protective layer. Stainless steel ball bearings are designed to resist corrosion better than most metals, but their performance depends heavily on the operating environment, material grade, and maintenance. Choosing the right alloy, following proper lubrication practices, and ensuring clean, dry conditions are essential steps to ensure longevity.

The bottom line: stainless steel is corrosion-resistant, not corrosion-proof. With awareness and proper handling, you can significantly minimize the risk of rust — ensuring your bearings stay strong, smooth, and dependable for years to come.